On the shop floor, it is not uncommon for operators to work with several different software systems during a single shift. In one system they record work, in another they report nonconformities, a separate application is used for maintenance records, and yet another for accessing documentation. Each switch means a new login, searching for the right function, and the risk of entering data in the wrong place. This fragmented approach increases errors, burdens users, and complicates the training of new employees.

A much more efficient solution is to use an MES system that integrates the different agendas, or at least provides a unified user interface for entering data into various backend systems (TQM, QMS, TPM, CMMS, APS, and others).

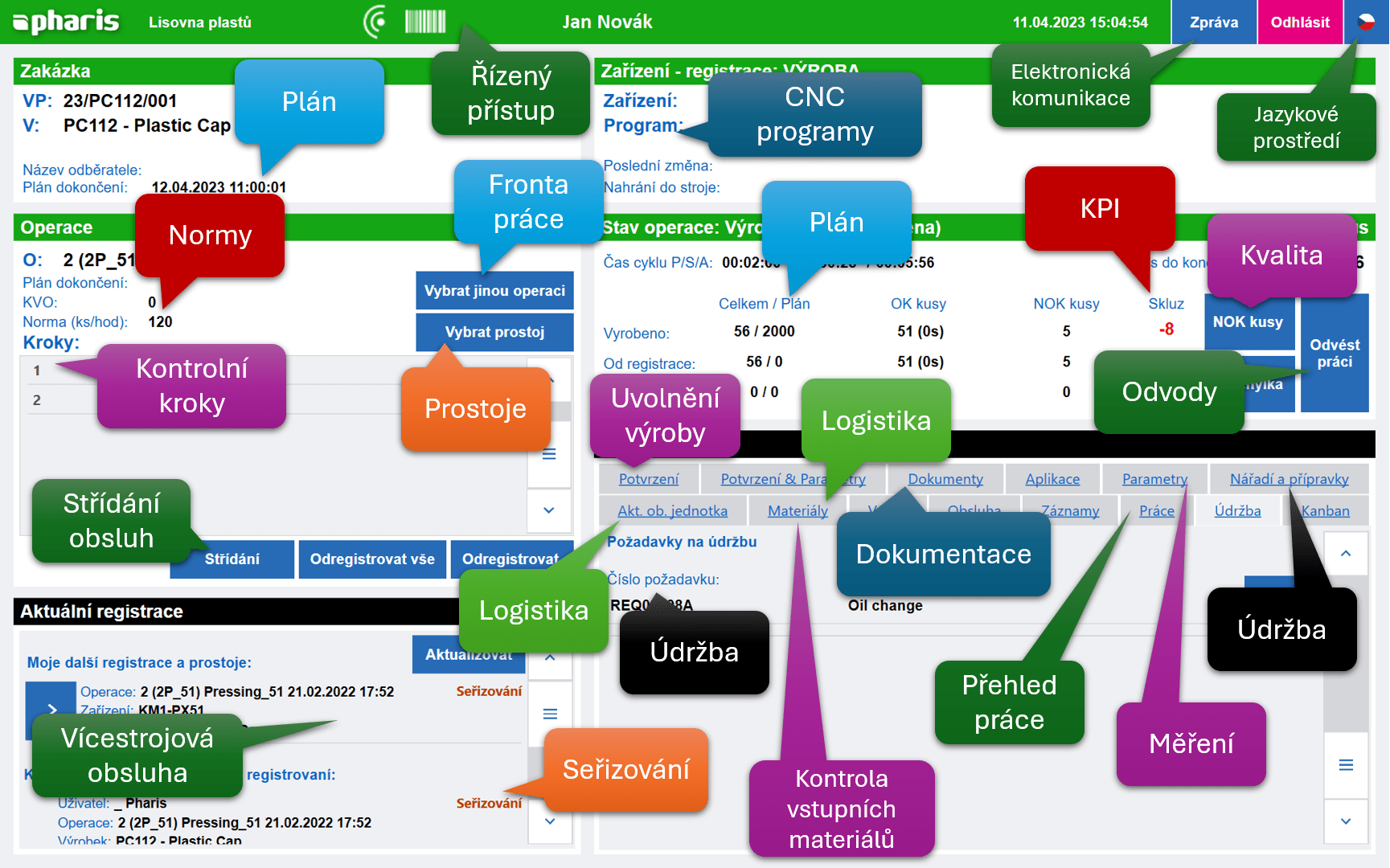

A practical example: MES PHARIS

MES PHARIS offers a single interface where the full range of manufacturing processes can be handled: work reporting, downtimes, nonconformities, maintenance, production planning, documentation, quality, CNC programs, and production analysis. It also supports control plans, measurements and parameter entry, production release, incoming material inspection, and packaging records. Most importantly, operators work with data from different agendas at one production terminal in a single unified interface.

We export and integrate data

Some data entered in the unified interface are transferred to specialized software for evaluation, while others are processed directly in modules integrated within the MES system. These modules (e.g. APS, maintenance, logistics, production control, or quality evaluation) cooperate with and influence each other, ensuring consistency of data and processes across the entire production.

Favorite external applications remain available

Thanks to this principle, it is still possible to use popular and long-established tools—for example, quality management software (for SPC evaluation) that employees are used to, or unified company reporting in Power BI (for monitoring KPIs). Here, MES serves as the central interface for data entry and integration, ensuring that every system (ERP, TQM, QMS, TPM, CMMS, …) receives the necessary information in the appropriate form.

Cross-correlation of data drives manufacturing processes

At the same time, it becomes possible to go further: data from different areas of production are automatically linked and correlated within MES. Downtimes can immediately affect planning in APS, quality inspection nonconformities can stop production and block materials in the warehouse, and preventive maintenance can be triggered based on actual reports from the shop floor. In practice, this means that shop floor processes react to each other without unnecessary delays, and decision-making is based on consistent, shared data.

You only see what you need in the system

In the integrated interface, each user has access only to the functions and processes they are authorized for, and nothing else is visible or usable. An operator, for example, only works with work reporting and downtime logging, a quality engineer has access to parameter measurements and control plans, a setter can adjust machines and manage NC programs, and a material handler deals with deliveries and incoming material inspection. This approach not only simplifies work and reduces errors but also complies with access control principles according to standards (e.g. RBAC).

Overview of the benefits of a unified integrated interface:

- Simplicity for users – a consistent logic and look, regardless of the specific process.

- Time savings – no switching between applications, just one login.

- Fewer errors – the system automatically routes data to the correct agenda.

- Easier training – new employees learn one environment, not several different ones.

- Data consistency – all records share a unified format, with no duplicates or incomplete entries.

- Consistency of data and processes – modules interact with each other and provide a unified view of production.

- Option to retain existing specialized tools – data can still be used in quality software or company reporting.

- Advanced integration – data in MES are interconnected and automatically influence processes.

- Better clarity – each user sees functions relevant to their role, still within the same interface.

- Lower IT administration costs – fewer installations, easier maintenance, and simplified terminal management.

Overview of the drawbacks of using multiple different software systems on production terminals:

- Confusion when deciding which system the data belong to.

- Time losses caused by switching and logging in.

- Risk of incorrect data entry.

- More complex training for new employees.

- Greater burden on IT due to managing and updating multiple applications.

- Higher requirements for performance and capacity of production terminals.

- No possibility of automatic data correlation across production areas.

A unified interface in MES brings comfort and simplicity to users, reliable high-quality data to management, and cost savings to the company. In contrast, running multiple different software systems on production terminals creates unnecessary complexity and inconsistency.

Miroslav Patočka

Product Owner & Chief Analyst

PHARIS